KVX offers flexible and reliable solutions for many different buckets and applications.

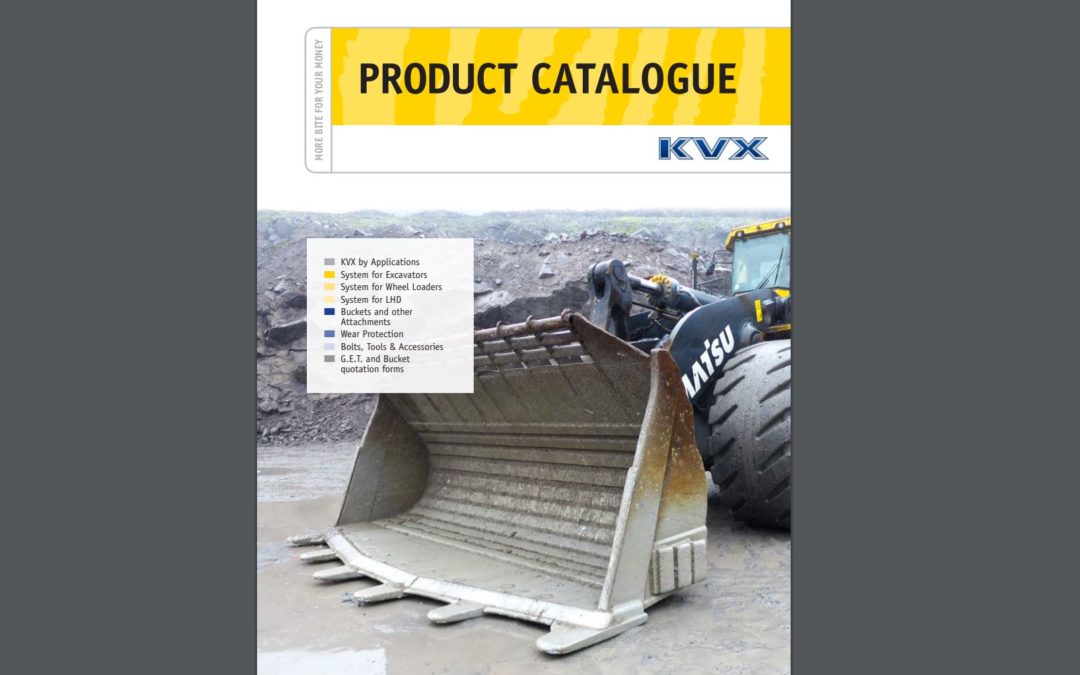

Launching the Product Catalogue is the annual highlight for us at KVX. The Product Catalogue is one of our most important sales materials, displaying our full range of GET and wear protection offerings.

Today KVX is Norway’s leading manufacturer of GET (Ground Engaging Tools), and a growing international player serving the construction, quarry and mining industries, while also offering products for a range of other severe industrial

applications.

KVX has also developed a highly attractive range of buckets and attachment products for excavators, wheel loaders and front shovel machines.

In the KVX Product Catalogue you will find important information about tools, installation procedures and techniques, etc. to ensure that you get the most out of our systems. Combined with our web site kvx.no this catalogue is a good tool to find the right GET and tooth system to suit any machine and application.

The 2022 edition of the catalogue has a new and improved graphic matrix, clearly displaying which GET systems and sizes suits buckets for different sizes and kinds of machines.

2023 product catalogue (PDF, english)

View all catalogues and brochures

Applications

KVX offers GET solutions for excavator and wheel loader buckets within a wide range of applications in construction, quarries, mining and tunneling.

Aggregate and crushing applications

The KVX bolt-on system offers excellent physical retention which significantly reduces the chance of tooth loss when loading crushers.

Limestone

KVX provides specially heat treated serrated cutting edges and tooth systems which are customized for handling limestone. Materials like limestone tend to create surface cracks caused by friction and heat.

Mining and underground

GET costs are closely connected to profitability in mining. KVX delivers a heavy duty solution for mining applications, both GET and complete buckets. KVX has decades of experience with underground systems and has supported mining operations all over the world.

Tunneling

KVX wearplates for tunneling offer superior strength and lifetime. Designed for most LHD – Load Haul Dump – machines of various sizes. The system features wear plates are made from KVX´s legendary Sagitta steel.

Road, railroad and construction

Construction contractors report KVX GETs providing lower cost per ton, hence better profitability.

Demolition and recycling

KVX GETs made from 500-600 Brinell rolled & forged Sagitta steel. Ensures the hardness, tensile strength and unrivalled toughness needed for demolition and recycling applications.

Dredging

The KVX system features a loaded retention system preventing the movement of GET items during operation. The traditional KVX system avoids losing pins and breakages of welded adapters. The bolt-on teeth are fixed, with no risk of the ingress of water and fines between moving surfaces.

Utility – small machines

KVX offers safe and well-proven systems for mini and idi excavators, skid steer Loaders, backhoe loaders and compact wheel loaders.

Special applications – extreme heat and cold

With the KVX system’s GET design, individual components tend to be larger and more thermally stable than conventional GET. The GET components can dissipate heat into the lip and bucket more effectively during hot slag handling. In the other end of the temperature scale – digging frozen ground in harsh cold – bolt-on weld free GET solutions provide some important advantages: Perfect penetration is one of them. No welding upon tooth or adapter replacement is another.

2023 product catalogue (PDF, english)

View all catalogues and brochures